Yuav ua li cas xaiv Surface Finish rau koj tus qauv PCB

Ⅲ Cov kev taw qhia kev xaiv thiab tsim cov qauv

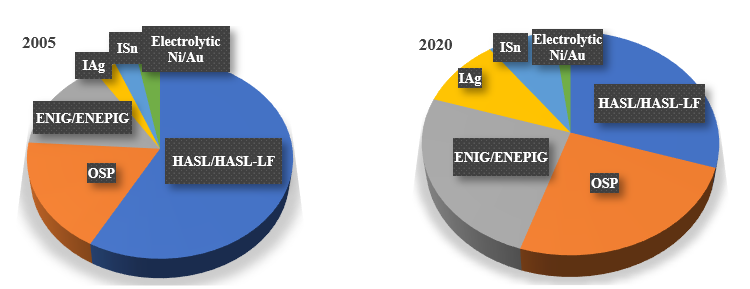

Raws li daim duab saum toj no qhia tau hais tias, PCB nto tiav daim ntawv thov tau sib txawv zoo kawg li 20 xyoo dhau los raws li kev siv tshuab tsim thiab muaj cov lus qhia ib puag ncig.

1) HASL Lead Dawb.Cov khoom siv hluav taws xob tau txo qis hauv qhov hnyav thiab qhov loj me yam tsis muaj kev cuam tshuam kev ua tau zoo lossis kev ntseeg siab nyob rau xyoo tas los no, uas tau txwv kev siv HASL kom zoo heev uas muaj qhov tsis sib xws thiab tsis haum rau cov suab zoo, BGA, cov khoom me me tso thiab plated los ntawm qhov.Cov cua kub ua kom tiav tiav muaj kev ua tau zoo (kev ntseeg siab, kev sib koom ua ke, ntau lub voj voog thermal thiab lub neej txee ntev) ntawm PCB los ua ke nrog cov ntaub qhwv loj thiab qhov sib txawv.Nws yog ib qho ntawm feem pheej yig tshaj thiab muaj tiav tiav.Txawm hais tias HASL thev naus laus zis tau hloov zuj zus mus rau tiam tshiab ntawm HASL cov hlau lead-dawb kom ua raws li RoHS cov kev txwv thiab WEEE cov lus qhia, cov cua kub theem tiav poob mus rau 20-40% hauv PCB fabrication kev lag luam los ntawm kev tswj hwm (3/4) thaj chaw no hauv xyoo 1980s.

2) OSP.OSP tau nrov vim yog tus nqi qis tshaj plaws thiab cov txheej txheem yooj yim thiab muaj cov ntaub ntawv sib koom ua ke.Nws tseem txais tos vim qhov no.Cov txheej txheem txheej txheem txheej txheem tuaj yeem siv dav hauv ob qho tib si ntawm cov qauv PCBs lossis qib siab PCBs xws li suab zoo, SMT, pab pawg thawj coj saib.Kev txhim kho tsis ntev los no rau phaj ntau txheej ntawm cov txheej txheem organic kom OSP sawv ntau lub voj voog ntawm kev sib tw.Yog tias PCB tsis muaj qhov kev sib txuas ntawm qhov chaw ua haujlwm lossis kev txwv lub neej txee, OSP yuav yog qhov zoo tshaj plaws ntawm cov txheej txheem tiav.Txawm li cas los nws flaws, rhiab heev rau tuav kev puas tsuaj, luv txee lub neej, nonconductivity thiab tsis yooj yim los soj ntsuam qeeb nws cov kauj ruam kom muaj zog.Nws tau kwv yees tias kwv yees li 25% -30% ntawm PCBs tam sim no siv cov txheej txheem txheej txheem organic.

3) ENIG.ENIG yog qhov nrov tshaj plaws ntawm cov txheej txheem PCBs thiab PCBs siv rau hauv ib puag ncig hnyav, rau nws qhov kev ua tau zoo ntawm cov qauv txheej txheem, solderability thiab durability, tsis kam rau tarnish.Feem ntau cov tuam txhab PCB muaj electroless npib tsib xee / immersion kub kab nyob rau hauv lawv Circuit Court boards factories los yog rhiav.Tsis xav txog tus nqi thiab kev tswj hwm tus txheej txheem, ENIG yuav yog qhov kev xaiv zoo tshaj plaws ntawm HASL thiab muaj peev xwm siv tau dav.Electroless npib tsib xee / immersion kub tau loj hlob sai nyob rau hauv 1990s vim yog kev daws teeb meem flatness ntawm huab cua kub leveling thiab tshem tawm cov organically coated flux.ENEPIG raws li kev hloov kho tshiab ntawm ENIG, daws qhov teeb meem ntawm lub ncoo dub ntawm electroless nickel / immersion kub tab sis thaum tseem kim.Daim ntawv thov ntawm ENIG tau qeeb me ntsis txij li kev nce nqi ntawm kev hloov pauv tsawg dua xws li Immersion Ag, Immersion Tin thiab OSP.Nws kwv yees li ntawm 15-25% ntawm PCBs tam sim no saws qhov tiav.Yog tias tsis muaj kev sib koom ua ke ntawm pob nyiaj siv, ENIG lossis ENEPIG yog qhov kev xaiv zoo tshaj plaws rau feem ntau ntawm cov xwm txheej tshwj xeeb rau PCBs nrog cov kev xav tau tshwj xeeb ntawm kev tuav pov hwm zoo, cov txheej txheem pob nyuaj, ntau hom kev sib txuas, dhau-qhov, kev sib txuas, thiab xovxwm haum tshuab, lwm..

4) Immersion Nyiaj.Raws li kev hloov pauv pheej yig dua ntawm ENIG, immersion nyiaj muaj cov khoom ntawm qhov chaw tiaj tus, zoo conductivity, nruab nrab lub neej txee.Yog tias koj lub PCB xav tau cov suab zoo / BGA SMT, qhov chaw me me, thiab xav tau kom muaj kev sib txuas zoo thaum koj muaj peev nyiaj tsawg, cov nyiaj immersion yog qhov kev xaiv zoo rau koj.IAg yog dav siv nyob rau hauv kev sib txuas lus cov khoom, tsheb, thiab computer peripherals, thiab lwm yam.. Vim hais tias ntawm unmatched hluav taws xob kev ua tau zoo, nws yog txais tos nyob rau hauv high zaus tsim.Kev loj hlob ntawm cov nyiaj immersion qeeb (tab sis tseem nce siab) vim qhov tsis zoo ntawm kev ua kom pom tseeb thiab muaj kev sib koom ua ke voids.Muaj li ntawm 10% -15% ntawm PCBs tam sim no siv qhov ua tiav no.

5) Immersion Tin.Immersion Tin tau nkag mus rau hauv cov txheej txheem nto tiav rau ntau tshaj 20 xyoo.Ntau lawm automation yog lub ntsiab tsav tsheb ntawm ISn nto tiav.Nws yog lwm qhov kev xaiv raug nqi rau qhov kev xav tau ntawm qhov chaw tiaj tus, zoo suab thaj chaw tso thiab nias-haum.ISn yog qhov tshwj xeeb tshaj yog tsim rau kev sib txuas lus backplanes rau tsis muaj cov ntsiab lus tshiab ntxiv thaum lub sijhawm ua haujlwm.Tin Whisker thiab lub qhov rais ua haujlwm luv luv yog qhov txwv loj ntawm nws daim ntawv thov.Ntau hom kev sib dhos tsis pom zoo muab cov txheej txheem intermetallic nce thaum lub sij hawm soldering.Tsis tas li ntawd, kev siv cov txheej txheem tin immersion raug txwv vim muaj cov carcinogens.Nws tau kwv yees tias kwv yees li 5% -10% ntawm PCBs tam sim no siv cov txheej txheem immersion tin.

6) Electrolytic Ni/Au.Electrolytic Ni/Au yog tus tsim ntawm PCB nto kho tshuab.Nws tau tshwm sim nrog kev kub ntxhov ntawm Printed circuit boards.Txawm li cas los xij, tus nqi siab heev zoo kawg nkaus txwv nws daim ntawv thov.Niaj hnub no, mos kub yog siv rau kub hlau nyob rau hauv nti ntim;Cov kub kub yog siv rau kev sib txuas hluav taws xob hauv qhov chaw uas tsis yog soldering xws li cov ntiv tes kub thiab cov nqa khoom IC.Qhov feem ntawm Electroplating Nickel-kub yog kwv yees li 2-5%.

Rov qabrau Blogs

Post lub sij hawm: Nov-15-2022