Plated Los ntawm Qhov PTH Txheej Txheem hauv PCB Hoobkas --- Electroless Chemical Copper Plating

Yuav luag tag nrhoPCBs nrog ob txheej txheej los yog ntau txheej siv plated los ntawm qhov (PTH) los txuas cov conductors ntawm cov khaubncaws sab nraud povtseg los yog tawm txheej, los yog tuav cov khoom txhuas hlau.Yuav kom ua tiav qhov ntawd, cov kev sib txuas zoo yog xav tau rau tam sim no kom ntws los ntawm lub qhov.Txawm li cas los xij, ua ntej cov txheej txheem plating, los ntawm qhov tsis yog qhov ua tau zoo vim cov ntawv luam tawm Circuit Court boards yog tsim los ntawm cov khoom siv uas tsis yog-conductive substrate (epoxy-iav, phenolic-paper, polyester-iav, thiab lwm yam).Txhawm rau tsim kom muaj kev sib haum xeeb txawm tias txoj hauv kev, txog 25 microns (1 mil lossis 0.001 nyob rau hauv.) ntawm tooj liab lossis ntau tshaj qhov teev los ntawm Circuit Board designer yuav tsum tso electrolytically rau ntawm phab ntsa ntawm lub qhov los tsim kom muaj kev sib txuas txaus.

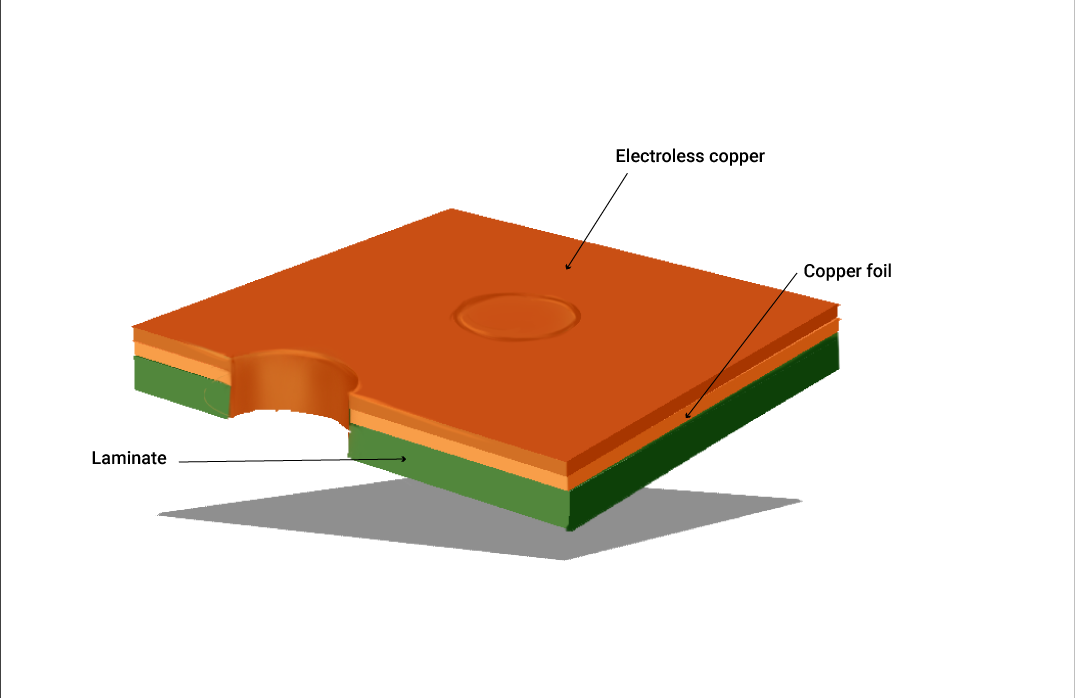

Ua ntej electrolytical tooj liab plating, thawj kauj ruam yog cov tshuaj tooj liab plating, tseem hu ua electroless tooj liab deposition, kom tau txais thawj txheej txheej ntawm phab ntsa ntawm lub qhov ntawm cov ntawv xov hlau.Ib qho autocatalytic oxidation-txo cov tshuaj tiv thaiv tshwm sim nyob rau saum npoo ntawm cov khoom tsis ua rau substrate los ntawm qhov.Nyob rau ntawm phab ntsa ib lub tsho nyias nyias ntawm tooj liab txog 1-3 micrometer thickness yog chemically deposited.Nws lub hom phiaj yog ua kom lub qhov nto ntawm qhov hluav taws xob txaus kom tso cai txuas ntxiv nrog tooj liab tso electrolytically rau cov tuab uas tau teev tseg los ntawm tus tsim hluav taws xob hluav taws xob.Dhau li ntawm tooj liab, peb tuaj yeem siv palladium, graphite, polymer, thiab lwm yam.Tab sis tooj liab yog qhov kev xaiv zoo tshaj plaws rau cov neeg tsim hluav taws xob hauv lub sijhawm ib txwm muaj.

Raws li IPC-2221A rooj 4.2 hais tias qhov tsawg kawg nkaus tooj liab tuab yog siv los ntawm electroless tooj liab plating txoj kev ntawm phab ntsa ntawm PTH rau nruab nrab tooj liab deposition yog 0.79 mil rau chav kawm Ⅰ thiab Class Ⅱ thiab 0.98 mil rauchav kawmⅢ.

Cov tshuaj tooj liab deposition kab yog tag nrho lub computer tswj thiab cov panels yog nqa los ntawm ib tug series ntawm tshuaj thiab rinsing da dej los ntawm lub overhead crane.Thaum xub thawj, lub pcb panels yog pre-kho, tshem tawm tag nrho cov seem ntawm drilling thiab muab zoo roughness thiab electro zoo rau cov tshuaj deposition ntawm tooj liab.Cov kauj ruam tseem ceeb yog cov txheej txheem permanganate desmear ntawm lub qhov.Thaum lub sij hawm kev kho mob, ib tug nyias txheej ntawm epoxy resin yog etched deb ntawm ntug ntawm lub puab txheej thiab cov phab ntsa ntawm lub qhov, los xyuas kom meej adhesion.Tom qab ntawd tag nrho cov phab ntsa ntawm lub qhov yog muab tso rau hauv chav da dej kom tau txais cov noob nrog micro-particles ntawm palladium hauv chav da dej.Lub da dej yog khaws cia nyob rau hauv ib txwm huab cua agitation thiab cov panels yog tas li txav mus los ntawm lub da dej kom tshem tawm tej huab cua npuas uas tej zaum yuav tsim nyob rau hauv lub qhov.Ib txheej nyias ntawm tooj liab tso rau tag nrho saum npoo ntawm lub vaj huam sib luag thiab drilled qhov tom qab da dej palladium.Electroless plating nrog kev siv palladium muab rau qhov muaj zog tshaj adhesion ntawm tooj liab txheej rau fiberglass.Thaum kawg ib qho kev tshuaj xyuas yog ua los xyuas qhov porosity thiab thickness ntawm lub tsho tiv no tooj liab.

Txhua kauj ruam yog qhov tseem ceeb rau tag nrho cov txheej txheem.Txhua qhov kev ua yuam kev hauv cov txheej txheem tuaj yeem ua rau tag nrho cov khoom ntawm PCB cov laug cam kom nkim.Thiab qhov kawg ntawm pcb yog qhov tseem ceeb hauv cov kauj ruam uas tau hais ntawm no.

Tam sim no, nrog rau cov qhov hluav taws xob, hluav taws xob kev sib txuas ntawm cov txheej sab hauv thiab tawm cov txheej txheem tsim rau cov boards.Cov kauj ruam tom ntej yog kom loj hlob tooj liab nyob rau hauv cov qhov thiab sab saum toj thiab hauv qab cov khaubncaws sab nraud povtseg ntawm cov hlau boards mus rau tej thickness - tooj liab electroplating.

Tag nrho cov automated tshuaj electroless tooj liab plating kab hauv PCB ShinTech nrog Txiav ntug PTH Technology.

Post lub sij hawm: Lub Xya hli ntuj-18-2022