HDI PCB Ua --- Immersion Kub nto kho

ENIG hais txog Electroless Nickel / Immersion Kub, tseem hu ua tshuaj Ni / Au, nws cov kev siv tau nrov tam sim no vim muaj kev lav phib xaub rau cov kev cai tsis muaj txhuas thiab nws tsim nyog rau PCB tam sim no tsim qauv ntawm HDI thiab nplua pitches ntawm BGAs thiab SMTs. .

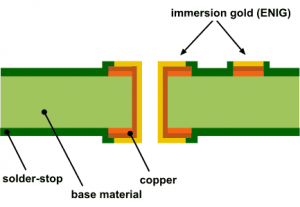

ENIG yog cov txheej txheem tshuaj lom neeg uas daim hlau nthuav tawm nrog Nickel thiab Kub, yog li nws muaj ob txheej txheej hlau txheej, 0.05-0.125 µm (2-5μ nti) ntawm immersion kub (Au) tshaj 3-6 µm (120- 240μ nti) ntawm electroless Nickel (Ni) raws li muab nyob rau hauv tus qauv siv.Thaum lub sij hawm tus txheej txheem, Nickel yog tso rau ntawm palladium-catalyzed tooj liab nto, ua raws li kub adhering rau lub nickel-plated cheeb tsam los ntawm molecular pauv.Cov txheej npib tsib xee tiv thaiv cov tooj liab los ntawm oxidation thiab ua raws li qhov chaw rau PCB los ua ke, kuj yog ib qho kev tiv thaiv kom tsis txhob tooj liab thiab kub ntawm kev tsiv mus nyob rau hauv ib leeg, thiab nyias Au txheej tiv thaiv cov nickel txheej kom txog thaum cov txheej txheem soldering thiab muab qis. tiv taus thiab ntub dej zoo.Qhov thickness no tseem zoo ib yam thoob plaws hauv lub rooj tsavxwm luam ntawv.Kev sib xyaw ua ke ua kom muaj zog tiv thaiv corrosion thiab muab qhov zoo tagnrho rau qhov chaw SMT.

Cov txheej txheem suav nrog cov kauj ruam hauv qab no:

1) Kev ntxuav.

2) Micro-etching.

3) Pre-dipping.

4) Siv lub activator.

5) Tom qab dipping.

6) Siv cov electroless npib tsib xee.

7) Siv lub immersion kub.

Immersion kub feem ntau yog siv tom qab siv lub npog ntsej muag, tab sis nyob rau hauv ob peb kis, nws yog siv ua ntej cov txheej txheem solder daim npog qhov ncauj.Obviously, qhov no yuav ntau dua tus nqi yog tias tag nrho cov tooj liab yog plated nrog kub thiab tsis yog dab tsi tshwm sim tom qab solder daim npog qhov ncauj.

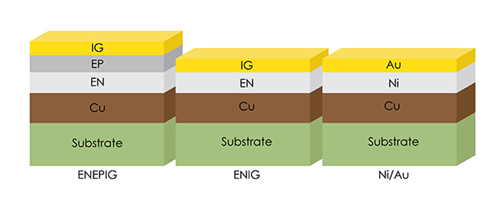

Daim duab saum toj no qhia txog qhov sib txawv ntawm ENIG thiab lwm yam kub nto tiav.

Technically, ENIG yog qhov zoo tshaj plaws kev daws teeb meem rau PCBs txij li nws cov txheej txheem tseem ceeb tshaj plaws thiab homogeneity, tshwj xeeb tshaj yog rau HDI PCB nrog VFP, SMD thiab BGA.ENIG yog qhov nyiam nyob rau hauv cov xwm txheej uas yuav tsum tau muaj kev tiv thaiv nruj rau PCB cov ntsiab lus xws li plated qhov thiab nias-haum thev naus laus zis.ENIG tseem tsim nyog rau cov hlau (Al) kev sib txuas ua ke.ENIG tau pom zoo rau cov laug cam xav tau kev koom nrog cov hom kev sib txuas vim nws tau sib xws nrog cov kev sib dhos sib txawv xws li SMT, flip chips, Through-Hole soldering, wire bonding, thiab press-fit technology.Electroless Ni/Au nto sawv nrog ntau lub voj voog thermal thiab tuav tarnish.

ENIG raug nqi ntau dua HASL, OSP, Immersion Silver thiab Immersion Tin.Black pad los yog Black phosphorus ncoo tshwm sim qee zaum thaum lub sijhawm txheej txheem uas muaj cov phosphorous ntawm cov txheej txheej ua rau muaj kev sib txuas tsis raug thiab qhov chaw tawg.Lwm downside tshwm sim yog undesirable magnetic zog.

Pros:

- Flat Surface - Zoo heev rau kev sib dhos ntawm lub suab zoo (BGA, QFP ...)

- Muaj zoo heev solderability

- Lub neej ntev txee (kwv yees 12 lub hlis)

- Kev tiv thaiv zoo

- Zoo heev rau tuab tooj liab PCBs

- Zoo dua rau PTH

- Zoo rau flip chips

- Haum rau Press-fit

- Hlau Bondable (thaum siv txhuas hlau)

- Cov hluav taws xob conductivity zoo heev

- Zoo cua sov dissipation

Cons:

- kim

- Dub phosphorus ncoo

- Electromagnetic cuam tshuam, Qhov Teeb Meem Tseem Ceeb Loss ntawm high-frequency

- Tsis Muaj Peev Xwm Rework

- Tsis haum rau Kov Contact Pads

Feem ntau siv:

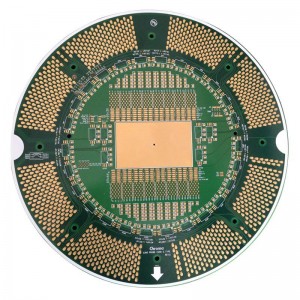

- Complex nto Cheebtsam xws li Pob Grid Arrays (BGAs), Quad Flat Packages (QFPs).

- PCBs nrog Mixed Package Technologies, nias-haum, PTH, hlau sib txuas.

- PCBs nrog hlau sib txuas.

- Cov ntawv thov kev ntseeg siab, piv txwv li PCBs hauv kev lag luam uas qhov tseeb thiab kev ua haujlwm ntev yog qhov tseem ceeb, xws li aerospace, tub rog, kev kho mob thiab cov neeg siv khoom siab.

Raws li tus thawj coj PCB thiab PCBA cov kev daws teeb meem nrog ntau tshaj 15 xyoo kev paub, PCB ShinTech muaj peev xwm muab txhua yam ntawm PCB board fabrication nrog qhov sib txawv ntawm qhov tiav.Peb tuaj yeem ua haujlwm nrog koj los tsim ENIG, HASL, OSP thiab lwm yam khoom siv hluav taws xob raws li koj qhov kev xav tau tshwj xeeb.Peb muaj cov nqi sib tw PCBs ntawm cov tub ntxhais hlau / txhuas thiab cov tawv tawv, yoog raws, tsis yooj yim, thiab nrog cov khoom siv FR-4, siab TG lossis lwm yam ntaub ntawv.

Rov qabrau Blogs

Post lub sij hawm: Jan-28-2023